The core functions and testing scope of the bathtub factory laboratory

our bathtub factory and practical value of enhancing customer trust by adding a new laboratory to the bathtub our factory,The addition of a new laboratory in the bathtub factory is a key measure to win customer trust through technical capability verification and transparent quality management The core values are reflected in three aspects: the authority of laboratory qualifications, the visualization of quality control, and the value-added of technical services. Specifically,Conduct an analysis based on industry practice and experience in standardization construction.

The laboratory of a bathtub factory is a crucial link to ensure product quality and safety, mainly focusing on performance testing and material inspection of bathtubs Certification and compliance testing have been carried out, covering bathtub products of various materials and functional types. The detection range includes acrylic and folded materials Mainstream bathtub categories such as stacked, wooden, inflatable, massage, ceramic, enamel, and glass fiber reinforced plastic 12. The laboratory needs Simulate actual usage scenarios and verify the product's performance in terms of structural strength, durability, safety, etc. through standardized tests For instance, the repeated folding fatigue test of folding bathtubs, the electrical safety test of massage bathtubs, etc.

The key test items and standard basis of the bathtub laboratory.Main test item classification Structure and safety performance.

Load-bearing test: Verify the bathtub's capacity to bear human weight to prevent deformation or damage during use.Leakage test: Check the sealing performance of joints and drainage systems through water storage tests. Impact resistance test: The impact resistance of the bathtub surface is evaluated by methods such as ball drop impact, referring to AS3558.11-1999 standard .

Material and environmental adaptability

Heat resistance and rapid heating and cooling: Simulate the effects of long-term immersion in high-temperature water and sudden temperature changes on bathtubs, in accordance with SN/T4847-

2017 and other standards 24 Thermal deformation test: To detect the stability of materials at high temperatures, such as the thermal deformation determination of plastic bathtubs as stipulated in AS3558.13-1999 Method.

Special function verification

Electrical strength test: For electrical products such as massage bathtubs, the electrical safety performance is tested in accordance with GB4706.73-2008

Folding fatigue test: For folding bathtubs, the durability of hinges and materials is evaluated through repeated folding.

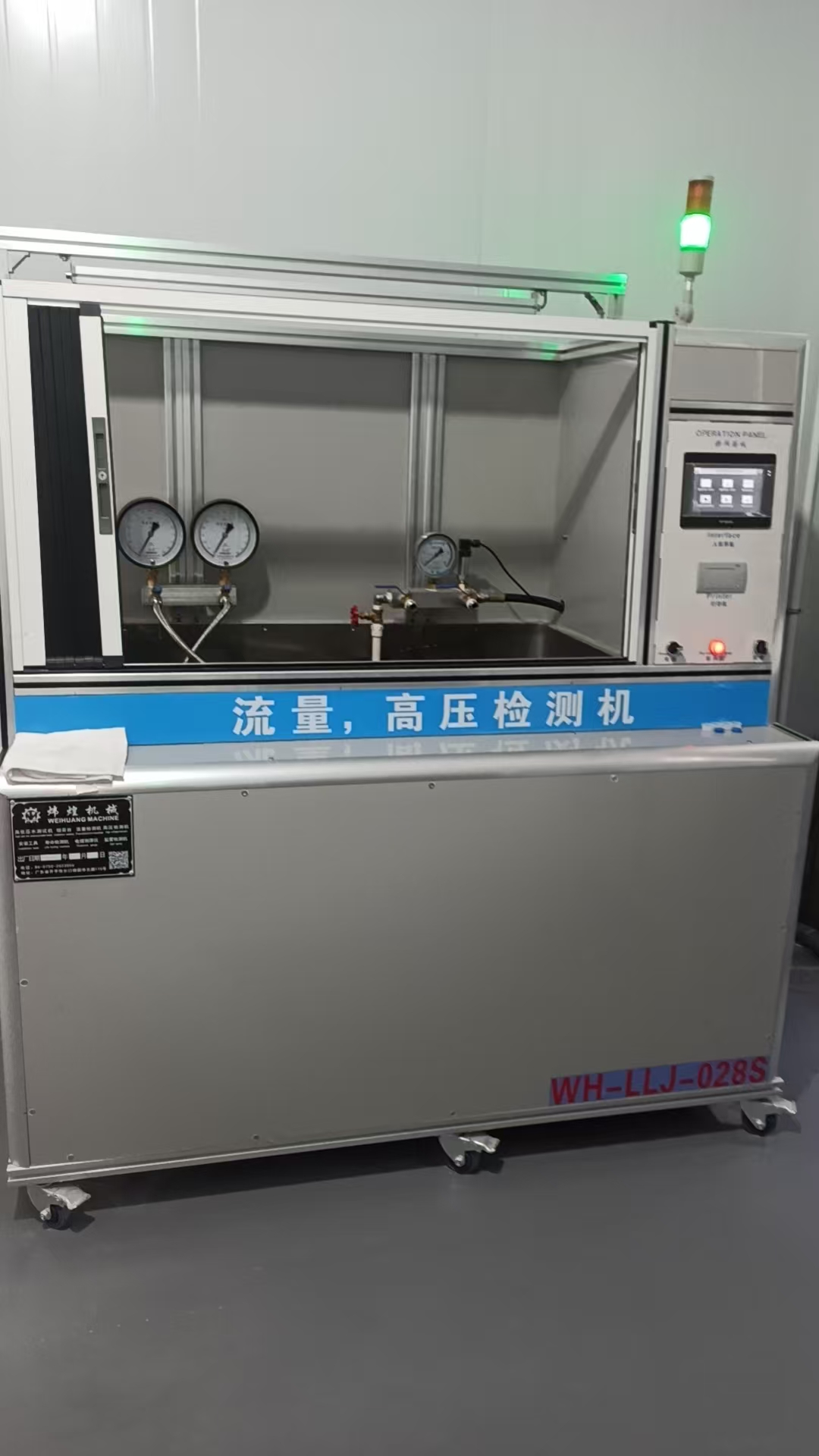

Key points of laboratory facilities and technical configuration

To meet the diverse testing requirements, the laboratory needs to be equipped with professional equipment and environmental simulation systems:

1. Mechanical property testing equipment: such as pressure testing machines (chassis pressure testing), drop ball impact testing machines, etc.

2. Environmental simulation device: including temperature control box (for sudden temperature change test) and constant temperature and humidity chamber (for material stability test)

3. Electrical safety testing instruments: Insulation resistance tester and electrical strength tester for massage bathtubs, in compliance

GB4706.73-2008 Standard 4.4. Chemical analysis equipment: It is used to test the chemical corrosion resistance of materials, referring to SN/T3253.1-2012 for the chemical analysis of sanitary ceramics

Academic performance requirements.

In addition, the laboratory needs to establish standardized operating procedures to ensure the accuracy and traceability of test data, such as pre-testing of samples Strict control of environmental parameters (temperature, humidity) for processing and testing .

The compliance and industry value of the laboratoryThe test results of the bathtub factory laboratory are directly related to whether the product meets the market access requirements, for example:

Domestic sales must comply with national standards such as QB/T series and GB series.

Export products must comply with international standards such AS AS(Australia), DIN(Germany), JIS(Japan), etc.

Through systematic testing in the laboratory, enterprises can detect design flaws (such as structural stress concentration) and material hazards (such as.) in advance.

The thermal deformation exceeds the standard, and the production process is optimized to reduce after-sales risks. Meanwhile, the test report is also an important support for a brand's reputation

For instance, obtaining group standard certifications such as T/CBCSA3-2018 can enhance consumer trust.For special categories such as children's bathtubs, the laboratory also needs to conduct safety tests in accordance with standards like XPS54-044-2003, with a focus on key tests The details such as anti-slip performance and the smoothness of the corners and edges reflect comprehensive protection for user safety.

Safety inspection: Strictly verify potential risks such as water leakage, electric leakage, and anti-slip to ensure user safety during use.Compliance certification: Issue test reports in accordance with domestic and international standards to support product market access and brand reputation building.

R&d support: Through material testing and environmental adaptability tests, provide data support for the optimization of new product design.

The technical configuration and process of the laboratory

Core equipment requirements.Mechanical testing equipment: Pressure testing machine (compressive strength), drop ball impact tester, folding fatigue testing machine.

Environmental simulation equipment: Constant temperature and humidity chamber (resistant to cold and heat alternations), thermal deformation tester.Chemical analysis equipment: Heavy metal detectors and environmental protection index analysis instruments.Electrical safety equipment: Insulation resistance tester and leakage protection device.